A common misconception about hydraulic cylinder speed is that faster operations lead to more efficient performances. However, this is usually untrue. Instead of seeking information on how to speed up hydraulic cylinders, OEMs and manufacturers should focus on selecting hydraulic cylinders that can handle speeds suited to their exact applications.

What Issues Are Caused by Incorrect Hydraulic Cylinder Speed?

While slow cylinders can cause stalls and related delays, the real destructive force comes from hydraulic cylinders that run too fast. When higher-than-intended speeds occur, the hydraulic cylinder can bottom out when the piston hits the head gland, resulting in blowouts or other damage. Signs of a cylinder running too quickly include:

- Excessive heat generation, causing damage to seals, component parts, and fluid degradation.

- Increased wear and tear

- High friction levels

- Reduced system lifespan

What Influences Hydraulic Cylinder Speed?

When designing a cylinder for new equipment, you will want to consider the stroke length, ambient temperature, and other elements to control the hydraulic cylinder speed. Regenerative circuits, properly sized pumps, seals made from specialty materials, and other design elements can all help achieve consistent speeds in harsh environments.

If speed issues occur during normal equipment operations, a few problems may be the root cause. Possibilities include, but are not limited to:

- Internal leakages

- Viscosity changes (depending on the pump and system design)

- Incorrect valve settings

- Mechanical issues

To address speed issues, it is essential to identify the specific root cause through careful troubleshooting and inspection. This may involve examining hydraulic components, adjusting valves, checking for blockages, ensuring proper fluid supply, or consult your operations manual or contact us today to learn more.

How to Calculate Hydraulic Cylinder Speed

Extension and retraction velocity determine hydraulic cylinder speed. Other hydraulic cylinder formulas may also apply. Visit our hydraulic cylinder calculators for assistance determining values for your cylinders.

Calculating Cylinder Extension Speed

Two calculations are required to determine your hydraulic cylinder’s extension speed. The first is the area of the piston. Piston area is calculated using the formula Ap=π x Dp2/4, where Ap refers to the piston area and Dp to the piston diameter. For example, say your cylinder features a piston diameter of 3”:

- Ap=π x 3in2/4

- Ap=065 in2

Using the piston area, you can then calculate the extension velocity using the formula of VE=231 x Q/Ap, where VE refers to the extension velocity, Q to the fluid flow in gallons per minute (GPM), and Ap to the piston area. To demonstrate, assume the same cylinder from above produces a fluid flow of 10GPM:

- VE=231 x 10/7.065in2

- VE=327 inches per minute

Calculating Cylinder Retraction Speed

Hydraulic cylinder retraction speed will always be faster than the extension speed as there is less volume inside the cylinder on the rod side. Three formulas are needed to accurately calculate your cylinder’s retraction speed: piston area, rod area, and retraction velocity rate.

After using the same calculation as above to determine piston area, calculate the rod area using the equation Ar=π x Dr2/4, where Ar refers to the rod area and Dr2 to the rod diameter. For example, let’s say your cylinder has a rod area of 1”:

- Ar=π x 1in2/4

- Ar=.785in2

Retraction velocity is determined using the formula Vr=231 x Q/(Ap-Ar), where Vr refers to the retraction velocity and Q to the fluid flow rates. Assuming a cylinder with a piston area of 7.065in2, a rod area of .785in2, and a fluid flow rate of 10GPM, your formula should be:

- Vr=231 x 10GPM/(7.065in2-.785in2)

- Vr=367 inches per minute

Aggressive Hydraulics Engineers Cylinders to Your Speed Specifications

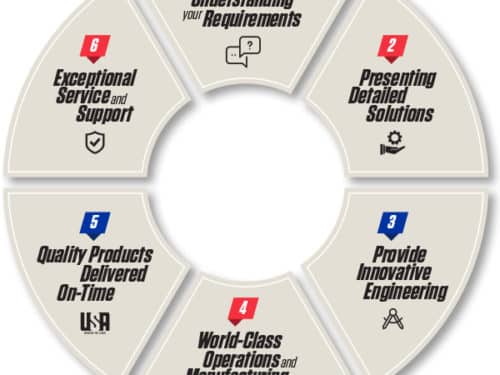

Aggressive Hydraulics designs and builds custom hydraulic cylinders to match your requirements, accounting for all speed needs, seal material considerations, pump size, and more. Our Purpose-Built™ hydraulic cylinders are USA-made, ensuring high-quality and long-lasting results. We have the extensive resources, industry-specific knowledge, and cylinder expertise you need.

Contact us or request a quote to begin.