Selecting the right ports and fittings for hydraulic cylinders is crucial to achieving optimal performance and avoiding future issues. With so many options available, knowing the strengths and limitations of each type can help make the best choice for each application. Here’s a quick look at the most common fitting types and when to consider each one.

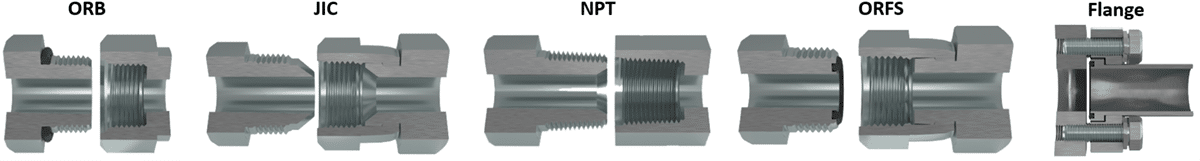

Common Fitting Types

ORB (O-Ring Boss)

- Overview: ORB fittings are our preferred choice at Aggressive Hydraulics due to their dependable sealing and ease of maintenance. Ideal for medium to high-pressure systems, ORB fittings resist over-torqueing and offer adjustable or fixed orientation options.

- Considerations: While they provide reliable performance, their pressure and temperature limits depend on the o-ring material used.

NPT (National Pipe Tapered)

- Overview: Known for their simplicity and cost-effectiveness, NPT fittings are widely used and don’t require additional seals or sleeves. However, they can be prone to leaking when overtightened and are harder to reassemble without compromising the seal.

- Considerations: Suitable for less critical applications but not recommended for reuse or when precise orientation is needed.

JIC (Joint Industry Council)

- Overview: JIC fittings offer interchangeability and can withstand high temperatures, thanks to their metal-to-metal seal. They are especially useful for removable fluid lines.

- Considerations: These fittings aren’t ideal for high-vibration applications, and they can be vulnerable to damage if overtightened.

ORFS (O-Ring Face Seal)

- Overview: ORFS fittings are highly reliable in high-pressure systems, especially those subject to vibration. Their flat face design and replaceable o-ring make them reusable and easy to maintain.

- Considerations: ORFS fittings are larger than other options and may have temperature limitations based on the seal material.

Flange (4-Bolt)

- Overview: The 4-Bolt Flange provides the highest pressure ratings and is ideal for large-diameter applications or systems in tight spaces where reliable, secure connections are essential.

- Considerations: While robust, these fittings are heavier and require more space, which may not be suitable for applications focused on weight reduction.

Making the Right Choice

When selecting ports and fittings, the specific application will ultimately define the best choice. Each type—whether ORB, NPT, JIC, ORFS, or Flange—offers distinct advantages suited to different conditions, from pressure requirements to assembly ease.

- ORB vs. NPT: For most medium to high-pressure applications, we recommend ORB fittings over NPT due to their strong sealing capabilities and reduced risk of contamination. However, NPT may still be suitable for applications requiring minimal reassembly.

- Adapters as a Last Resort: While adapters are available for compatibility, minimizing their use reduces potential leak points and system complexity.

- JIC and ORFS Options: JIC is ideal for fluid lines that need frequent disconnections, while ORFS fittings perform exceptionally well in high-vibration and high-pressure environments.

At Aggressive Hydraulics, we help tailor port and fitting choices to your unique application requirements, ensuring your hydraulic system operates reliably and efficiently under the conditions it’s built for.