Demolition equipment applications are some of the toughest in the world. This specialized equipment is subjected to hours of hard and dirty work, lifting tons of material. Often overworked and abused, this specialized equipment serves very special purposes. Let’s look at each and how hydraulic cylinders play a role in the demolition process.

Excavators are used to topple one and two story buildings by an undermining process. The strategy is to undermine the building, while controlling the manner and direction in which it falls. Engineers work to determine where to undermine the building at. The excavator consists of a boom, a dipper, and a bucket attached to the end. Hydraulic cylinders operate the movement of the boom and dipper to position the bucket for excavation, while additional hydraulic cylinders are used to control the force and motion of the bucket used for digging, clawing, and demolishing the structure and the area around, to weaken it.

High reach demolition excavators are used for tall buildings where explosive demolition is not possible. Excavators with shear attachments are typically used to dismantle steel structural elements. The shears work like large hydraulic operated scissors backed by thousands of pounds of hydraulic force, that cut, tear, and twist sections of the structure away. Hydraulic hammers are used for concrete structures to crush concrete to a manageable size, allowing for the removal of the steel reinforcement and beams by the excavator.

Mini-excavators are used for very tall concrete buildings, where high reach demolition with an excavator is not safe or practical. This “inside-out” method allows remotely operated mini-excavators to demolish the building from the inside, whilst maintaining the outer walls of the building as a scaffolding as each floor is demolished. The hydraulic cylinders used in these mini excavators are similar to standard excavators with much less power, force and size.

A wrecking ball on a crane is used in some demolition cases to demolish the structure down to a manageable height. Undermining is then performed to remove the rest of the structure. The same hydraulic cylinders used in crane operations are employed. The hydraulic cylinder’s forces are utilized in a different way, to create momentum in a cast iron ball suspended from the crane with enough force to demolish external walls of the structure.

Clearing rubble and debris is done with loaders, bulldozers, and dump trucks. These employ hydraulic cylinders in the traditional fashion to list dump bodies, raise and lower a blade, and pick up debris to load into a dump truck. Bulldozers are frequently equipped with “rakes” (thick pieces of steel that resemble an I-beam) that are used to ram building walls for final demolition operations. Skid loaders and mini-loaders will also be used to take materials out demolition sites and to sort steel.

On the horizon, a new method of demolishing buildings is being put into practice which involves using computer-controlled hydraulic jacks to support the bottom floor as the supporting columns are removed. Once clear, the hydraulic jacks lower the floor and this process is repeated for each remaining floor. This technique is thought to safer and more environmentally friendly, and is useful in areas of high population density. It represents the future of hydraulic cylinder technology in demolition.

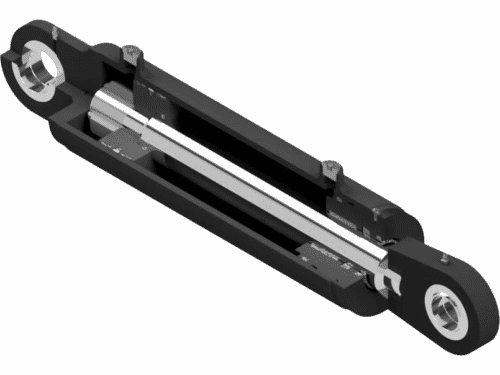

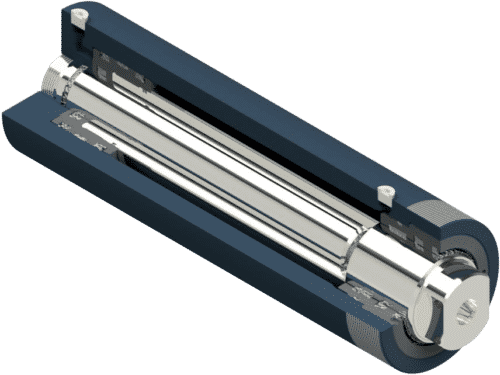

A single hydraulic cylinder failure on a machine can put a demolition project weeks behind schedule. Aggressive Hydraulics® can help keep your most important demolition machinery in working order by developing new Purpose-Built™ cylinders for your demolition application. Contact Aggressive Hydraulics today at (866) 406-4100 and let our Hydraulic Cylinder Specialist® work for you.