Mobile cranes are found on job sites across markets, including construction, demolition and scrap, material handling, mining, and more. To operate safely and efficiently during critical jobs, hydraulic cranes use hydraulic cylinders to move, lift, and reposition heavy loads.

How Hydraulic Cranes Function

Hydraulic cranes are usually powered by a combination of a combustion engine, motors, and hydraulic cylinders. Pressurized fluids generate a large amount of power. Generally, two pistons are used in crane hydraulics. When one piston becomes compressed, the other extends, moving the crane and allowing it to lift objects.

What are Hydraulic Cylinders in Cranes Used For?

Hydraulic cylinders allow cranes to function at a high level. While most use telescopic designs for normal operations, which hydraulic cylinder is best for your machinery can vary and may include:

- Single-acting telescopic cylinders

- Double-acting telescopic cylinders

- Welded rod cylinders

- Position sensing smart cylinders

- Integrated valve cylinders

Hydraulic Cylinders for Crane Booms

Crane booms are the arm used for handling loads. Depending on the construction of your crane, booms often include a jib, or lattice structure that extends from the boom, for enhanced operational capacities. Two main types of crane booms are used to complete industrial jobs:

- Folding crane booms feature a folding boom arm, enabling the crane to have a range of reach and mobility. Hydraulic cylinders provide support at each stage of articulation.

- Fixed crane booms, as implied by the name, are comprised of a fixed or stiff boom that generally telescopes instead of folding out. This allows the crane to lift extremely heavy or oversized loads.

Truck-Mounted Hydraulic Cranes

Truck-mounted cranes are an excellent mobile solution for jobs involving remote locations. They rely on an internal hydraulic system to hoist weighty loads while also being mounted on wheels to move from place to place at your job site. Due to the versatile operations of truck-mounted cranes, your best hydraulic cylinder option may include:

- Boom hoist lift cylinders

- Counterweight mover cylinders

- Jib boom cylinders

- Steering cylinders

- Telescopic extension cylinders

- And many others!

Cylinders for Hydraulic Gantry Crane Systems

Gantry cranes function differently than traditional hydraulic bridge cranes. Instead of using an overhead assembly, gantry systems straddle the work area and are ideal for extreme lifting operations. They are generally fixed in their location or mounted on rails, and they require heavy-duty hydraulic cylinders to manage their excessive loads. They are ideal for sites with space restrictions where overhead cranes cannot fit.

Reach New Heights with Purpose-Built™ Hydraulic Cylinders for Cranes

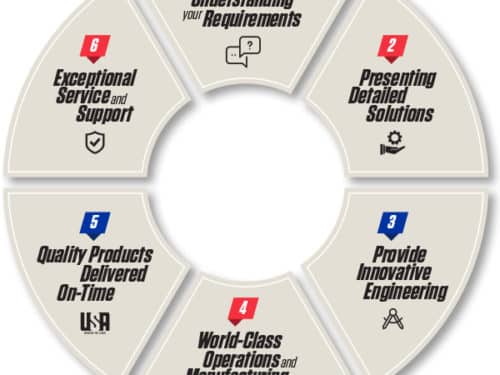

Whether you’re an OEM who builds cranes, a reseller looking for quality cylinders, or an integrator assembling crane components for your client, Aggressive Hydraulics is here to help. We are a leading USA-owned and operated manufacturer of hydraulic cylinders and will design, engineer, and deliver cylinders to meet your exact specifications.

Contact us or request a quote when you’re ready to enhance your crane operations with Purpose-Built™ cylinders that deliver reliable performances over long operational lifespans.