The food processing industry is a large market that completes a wide variety of processes, applications, and operations. From mixing batter and blending thick candy to loading crates of beverages or packaging cosmetics, food and beverage applications require heavy-duty machinery that performs as designed without contaminating products. Regardless of operations, all equipment within food processing plants, including cylinders, must be rust-resistant, hygienic, and food safe.

Are Pneumatic Systems or Hydraulic Cylinders Better for Food Processing Plants?

Depending on specific operations, food processing plants use pneumatic or hydraulic systems to keep processes running efficiently.

Pneumatic systems are applied in food and beverage productions that require precision operations for delicate processes, such as positioning baked goods for decoration, lifting eggs, and similar. Hydraulic cylinders deliver heavy-duty functions such as manipulating packaged goods, stirring thick or heavy ingredients, and powering conveyor lines.

In general, hydraulic cylinders deliver more force, feature higher durability, and have lower maintenance requirements than their pneumatic counterparts while still providing accurate results for exacting applications.

Hydraulic Cylinders Designed for Manufacturing & Packaging Food or Beverages

Hydraulic cylinders for food processing are designed with this industry’s unique needs in mind. Food and beverage manufacturing and packaging involve high pressures, extreme temperatures, damp or steamy environments, and other challenges. Food-safe hydraulic cylinder options include:

- High Pressure Hydraulic Cylinders

- Pre-Engineered Hydraulic Cylinders

- Or a different custom configuration!

No matter your selected hydraulic cylinder type, a few key design aspects must be considered for food processing plants.

Stainless Steel Hydraulic Cylinders for Food & Beverage Plants

Hygienic materials that withstand constant and harsh washdown procedures are essential for any food processing, manufacturing, or packaging line. Stainless steel hydraulic cylinders are the best solution. Advantages of stainless steel cylinders in food and beverage plants include:

- Excellent corrosion and rust resistance

- High tensile and yield strength

- Excellent machinability to meet custom needs

- Non-absorbent and easily finished with smooth surfaces

- Resistant to pitting, chipping, scoring, and other damages

Food-Grade Seals & Lubricants for Enhanced Operations

All aspects of food processing hydraulic cylinders must match or exceed strict cleanliness guidelines, including seals, lubricants, and other component parts. When designing a hydraulic cylinder for food processing, only use food-grade seals made from safe materials, such as high-performance polymers. Additionally, incorporate biodegradable hydraulic fluids and lubricants that will not contaminate products.

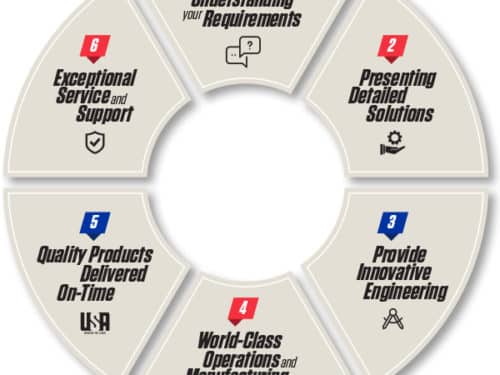

Purpose-Built™ Hydraulic Cylinders for Food Processing Plants

Partnering with an experienced hydraulic cylinder manufacturer is the best way to ensure you receive high-quality cylinders that match your specifications. Aggressive Hydraulics is here to help. We have the industry expertise and in-the-field knowledge to purpose-build custom cylinders that will enhance any food and beverage packaging or manufacturing process.

Contact us to learn more about our services and capabilities. Request a quote to begin your order.