How Extreme Heat and Cold Affects Hydraulic Systems

Hydraulic systems are made to handle demanding work conditions and harsh environments. But even the most rugged, high-performing equipment can fail under certain conditions. In work environments involving high and low temperatures, the hydraulic cylinders and components of these powerful systems are especially prone to damage.

Whether you operate industrial or mobile hydraulic equipment, these tips will help you understand the effects of high and low temperatures on hydraulic systems and how to protect them from damage.

Protecting Hydraulic Cylinders in Extreme Heat

All hydraulic systems generate heat during operation. Extremely high temperatures, however, whether it’s from mechanical or environmental sources, can do a number on your hydraulic system.

High Temperatures and Hydraulic Fluid Viscosity

You know how oil thins out once you add it to a hot pan? Well, heat has that same effect on hydraulic fluid and lubricants. In fact, heat is considered a type of hydraulic cylinder fluid contamination because it changes the chemical properties, resulting in lower fluid viscosity and oxidation. These changes both affect how well fluid lubricates hydraulic cylinder components. Inadequate lubrication increases friction, making your hydraulic cylinders and components more prone to damage and wear.

Changes to Hydraulic Cylinder Seals and Hoses in High Temperatures

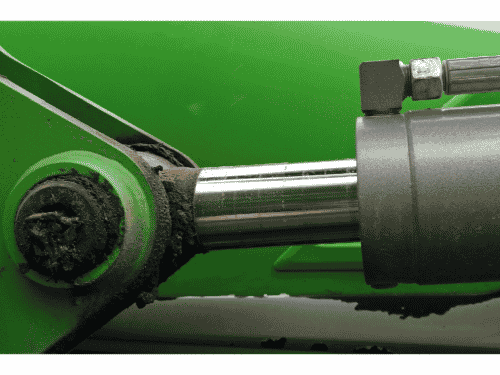

Extremely high temperatures can alter material properties, causing seals and hoses to lose resistance to tearing, abrasion, or friction. Compromised seals can introduce moisture, grime, and air into your hydraulic fluid and cause system failure. Construction and other applications involving prolonged exposure to extreme heat should consider Viton™, PTFE, or other materials with high temperature ratings.

Protecting Hydraulic Cylinders in Extreme Cold

Aggressive Hydraulics is based in Minnesota—we know cold! We also know that exposure to low temperatures is hard on hydraulic cylinders, especially the seals and fluid.

Low Temperatures and Hydraulic Fluid Viscosity

Hydraulic fluid has a freezing point of -10°F (-23°C), but even temperatures above that can change fluid viscosity. Cold temperatures cause fluid to thicken, making it more difficult for the fluid to move through your hydraulic system. Lubricants are also temperature-sensitive and can harden or lose lubricity in extreme cold.

Using hydraulic fluid with a lower viscosity grade can help prevent hydraulic cylinder failure in extreme cold. Another way to maintain fluid viscosity in low temperatures is using an externally mounted heat source. You can find several types of heating elements on the market designed to keep hydraulic fluid at the right temperature and viscosity.

How Cold Affects Hydraulic Cylinder Seals and Components

Elastomer and thermoplastic hydraulic seals shrink and harden under cold conditions, making sealed components more prone to leaks. Bad seals cause hydraulic cylinder failure, so it’s important to protect sealed components from frigid conditions.

Temperature ratings for hydraulic seals and hoses vary widely based on the material type. If you plan to use your hydraulic cylinders in low temperatures, choose components that have a low temp rating and are compatible with your hydraulic fluid type.

Preventative Maintenance and Using the Right Parts Makes a Difference

Performing regular preventative maintenance, along with understanding your mobile equipment application and operating environment, will help keep your hydraulic system in top condition. Check fluid levels regularly and inspect seals and hoses for signs of wear. Replacing bad fluid and worn parts right away will prevent bigger (and more expensive) issues down the road.

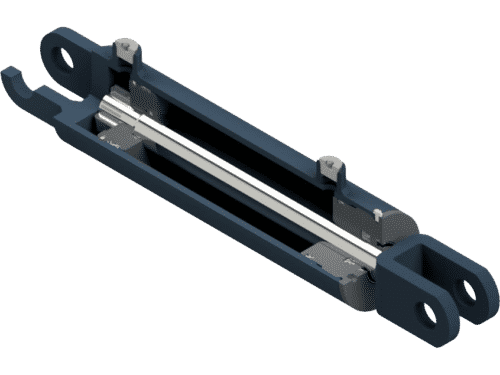

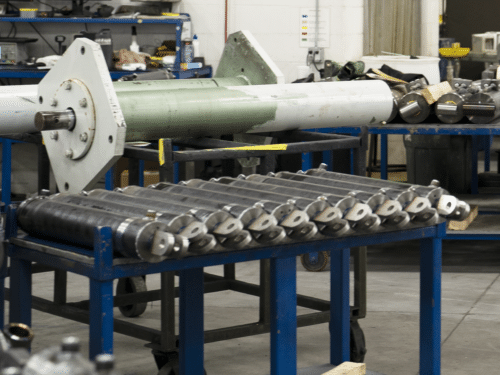

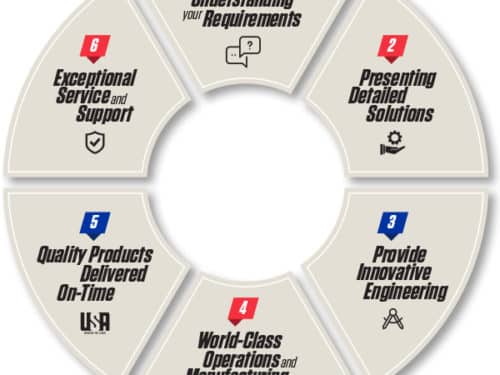

Aggressive Hydraulics has the parts you need, from custom, performance-built cylinders to high-quality seals and components. Our hydraulic cylinders are made in the USA and designed to meet the demands of your specific application and work environment. Give us a call to discuss your requirements!