Quality and precision is essential in the manufacture of a Purpose-Built™ ® hydraulic cylinder. From the sourcing of materials, to engineering, manufacture, painting and even shipping requires an attention to detail that ensures the longevity of your fluid power equipment. What exactly does quality and precision mean in hydraulic cylinder design and manufacturing though?

Quality and precision starts with sourcing raw materials and components. Often, not only are there long lead times that come from international shipping, but components sourced overseas are subjected to inferior fabrication methods and substandard quality of materials. A lack of quality in raw materials and components can mean higher maintenance costs, and more down time for the fluid power equipment users due to fatigue, surface pitting, contaminants in the alloys.

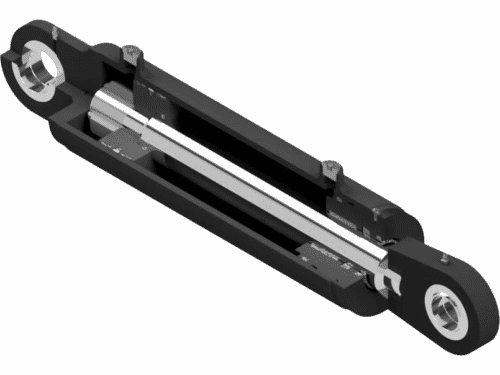

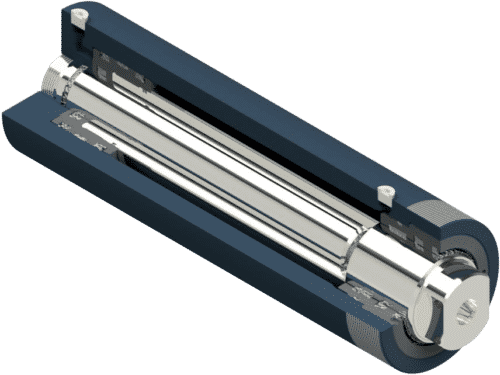

Engineering a Purpose-Built™ ® hydraulic cylinder to exact specifications requires a level of precision gained from special tools. A Purpose-Built™ ® hydraulic cylinder requires an understanding of an application’s specific rigors, environmental challenges, and precise measurements be taken into account. Engineers with knowledge across multiple industries, utilize state-of-the-art CAD/CAM technology can design Purpose-Built™ ® hydraulic cylinders that operate to specs within a thousandth of an inch. Finite element analysis is utilized to determine strengths and weaknesses of a hydraulic cylinder and how it will react under stress. This ensures the right hydraulic cylinder for the application.

Manufacturing ties raw materials, components and engineering together to produce a high quality finished product. State-of-the-art welding techniques including robotics are utilized to ensure repetitive and consistent welds that meet the design specifications. CNC machinery is put to use to produce more accuracy than the human eye, and hand is capable of detecting. This high tech equipment backed by qualified machinists and certified welders finish out the manufacturing process and allow for ongoing quality control reviews.

Every hydraulic Cylinder is then assembled by certified Fluid Power Specialists and hydraulic cylinder experts. After final assembly is complete, our experts test every hydraulic cylinder to exact specifications called for in the application and design. Painting is the final step, and is performed in a controlled environment which ensures a lasting finish that protects not only the hydraulic cylinder, but the job it performs for years to come.

At Aggressive Hydraulics®, quality isn’t a department, it’s a complete system that embraces quality at the source. Quality, precision, and integrity is a critical part of everything we do and we diligently adhere to the highest quality standards throughout the entire process. If you’re in the market for a quality Purpose-Built™ ® hydraulic cylinder, contact Aggressive Hydraulics® Hydraulic Cylinder Specialists® today at (866) 406-4100 and put quality and prevision to work for you.