Every part of a hydraulic cylinder, no matter how small, affects performance and longevity. Hydraulic seals have a particularly critical role in your cylinder design because they prevent leaks and fluid contamination. In the case of buffer seals, they also help protect other parts of your rod sealing system from damage.

Rod buffer seals are ring-shaped and sit between the wiper seal and rod guide ring in the hydraulic cylinder, creating a secure seal between the cylinder head and rod. These hydraulic seals lubricate the rod seal and wiper by allowing a small amount of oil to pass through the seal lip during operation.

But the most important function of buffer seals is absorbing pressure spikes during cylinder operation to protect the rod seal from damage. For heavy-duty applications especially, using rod buffer seals will improve cylinder performance and extend the operational life.

Common Types of Buffer Ring Seals for Hydraulic Cylinders

There are three primary types of buffer ring seals used in rod seal systems. The style you choose for your hydraulic cylinder design depends primarily on whether your application’s pressure requirements. Operating temperature is also important because it determines the material requirements for your buffer seal.

- Lip seals with backup rings: Designed to provide optimal sealing in heavy-duty, high-pressure applications, this buffer seal has a “pump-back” design to prevent pressure trapping.

- Lip seals without backup rings: These rod buffer seals let lubrication pass through but are not as effective as absorbing pressure spikes as seals with a backup ring. Because of this, these buffer seals should not be used in heavy-duty applications.

- Glide ring seal with O-ring energizer: Best for light- or medium-duty applications, these buffer ring seals feature a lip seal combined with an O-ring.

What to Look for In a Rod Buffer Seal Design

Too little lubrication passing through causes friction that affects hydraulic seal performance and causes premature wear, thus shortening rod seal life. A good buffer ring seal allows enough lubrication to pass through while maintaining a tight seal to absorb pressure spikes.

It is also crucial for buffer seals to vent intermediate pressure build-up between the rod seal and buffer seal. Failure to adequately vent pressure prevents the buffer seal and rod seal from effectively working together to absorb pressure. These and other factors can contribute to hydraulic cylinder failure over time.

Material is also essential and should be chosen based on the operating pressure, temperature, and the type of media the seal will be exposed to in the hydraulic system.

Incorporating Custom Hydraulic Seals in Your Cylinder Design

Standard buffer ring seals can work in a pinch but will not deliver the same results as custom hydraulic seals made for your application. Everything from the profile selected and the material used is important in ensuring performance and longevity. Enlisting the help of a hydraulic cylinder expert can help you find the right buffer seal for your application.

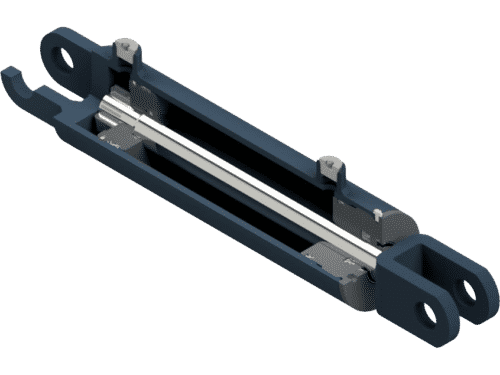

Aggressive Hydraulics builds high-quality rod buffer seals into every custom cylinder design. Our Purpose-Built™ design process ensures your hydraulic seals and components will be the right size, shape, and material for your equipment, application, and operating environment. Get in touch with us to learn more!