In a rephasing hydraulic cylinder system, there are typically two or more hydraulic cylinders in parallel. Each cylinder has its own piston and hydraulic chamber. These cylinders are linked together by a common hydraulic fluid source and a series of interconnected hydraulic lines or passages. The rephasing mechanism within the cylinder system ensures that all the connected cylinders extend or retract simultaneously and move at the same speed. This synchronization is achieved by the proper arrangement of valves, check valves, or flow dividers within the hydraulic system.

Advantages & Disadvantages of Rephasing Hydraulic Cylinders

Rephasing hydraulic cylinders offer advantages such as increased stability, improved load distribution, and enhanced control over complex hydraulic systems. They are often used in various industries, including construction, manufacturing, agriculture, and aerospace. Other advantages include:

- No necessary mechanical connection between actuators

- No devices or plumbing required for hydraulic resynchronization

- No potential for constant parasitic power loss

Rephasing hydraulic systems are not right for every job. They can be more complex and expensive compared to single-cylinder systems, potentially leading to higher maintenance requirements. The risk of fluid leakage and the lack of inherent position control are additional drawbacks. The decision to use rephasing hydraulic cylinders should consider the specific application requirements, weighing the benefits against the associated complexity, cost, and limitations.

How Rephrasing Hydraulic Cylinders Work

The most important difference between a rephasing hydraulic cylinder and a standard double-acting rod design or displacement cylinder is the inclusion of built-in passageways to achieve resynchronization in your system. They can be included at the cap end, rod end, or both ends of a rephasing hydraulic cylinder, allowing hydraulic oil to bypass the piston when the cylinder is extended or retracted.

Rephasing Hydraulic Cylinders in a Series

When arranging rephasing hydraulic cylinders in a series, the cylinder bore and cylinder rod sizes are always different. The rods extend or retract equally when flow is applied to the first or last hydraulic cylinder. This operational capacity removes the need for mechanical connections, flow dividers, and other devices.

Rephasing Parallel Hydraulic Cylinders

Parallel rephasing hydraulic cylinder systems are usually less complex than series systems. Parallel hydraulic systems are always used in pairs and utilize cylinders with the same bore and rod sizes. Both hydraulic cylinders extend the same amount at the same time.

Troubleshooting Tips for Rephasing Hydraulic Systems

While rephasing hydraulic cylinders can improve operations, they also create opportunities for issues to occur, particularly cylinder drift (also called cylinder creep) and failure to stay synchronized.

Correcting Cylinder Drift

Cylinder drift in rephasing cylinders can be addressed by bleeding air ingested into the system during normal operations. The solution is to rephase your system, which can be completed by fully extending the cylinder before actuating the cylinder valve for 30 seconds. Actuating the cylinder valve may take more or less time depending on the age of your cylinder, how often you bleed the air, and other factors.

Check Cylinder Rods Before Resynchronization

Hydraulic systems generally fall out of synchronization due to issues in one cylinder. Before resynchronization can occur, you must identify the damaged cylinder by checking the cylinder rods:

- Extend the cylinders fully, then retract approximately 2” from the rephasing position

- Disconnect all hydraulics from machinery

- Measure the length of each extended cylinder rod

- Allow the equipment to stand for an extended time

- Remeasure the rods

- Compare the before-and-after lengths to find the problem cylinder

- In a clean environment, disassemble the problem cylinder to diagnose the issue

Purpose-Built™ Hydraulic Cylinder Resources to Support Your Goals

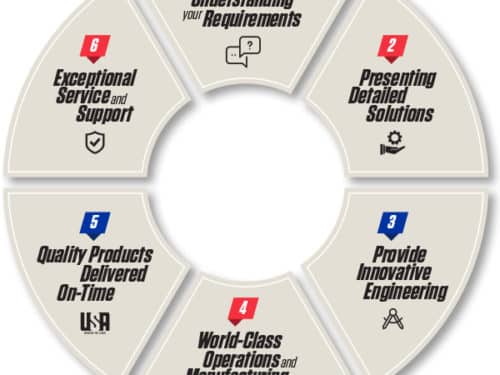

In addition to designing, engineering, and manufacturing high-performance hydraulic cylinders Purpose-Built™ to your specifications, Aggressive Hydraulics is your #1 source for reliable and trustworthy hydraulic cylinder resources. We’ve got the expertise and knowledge you need, from practical guides to cylinder calculators and beyond.

Contact us or request a quote to learn more about rephasing hydraulic cylinders and other custom products. Our engineers are standing by to begin building your best cylinder solution.