Hydraulic cylinders come in different designs, but two types often pop up when looking for replacement parts: NFPA cylinders and mill-duty cylinders. Anyone not familiar with the differences might wonder which to choose. And plenty of people probably have an opinion on which is they think is “better.”

But the important thing to remember is that the difference between NFPA and mill-duty cylinders has nothing to do with quality. Both have distinct advantages, so what it all comes down to is your application.

NFPA Cylinders

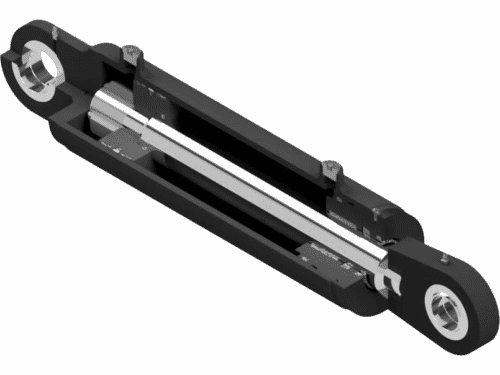

NFPA (short for National Fluid Power Association) cylinders are modular, predesigned hydraulic or pneumatic cylinders. These cylinders are designed for interchangeability and have the same standardized design, regardless of the manufacturer. With an NFPA cylinder, you can choose from standard bore sizes, rod diameters, port sizes and locations, stroke lengths, and mounting dimensions.

Consider NFPA hydraulic and air cylinders an “off-the-shelf” product made to handle most standard equipment requirements. They will meet basic needs, but the design is limited to what meets NFPA hydraulic cylinder standards.

Mill Duty Cylinders

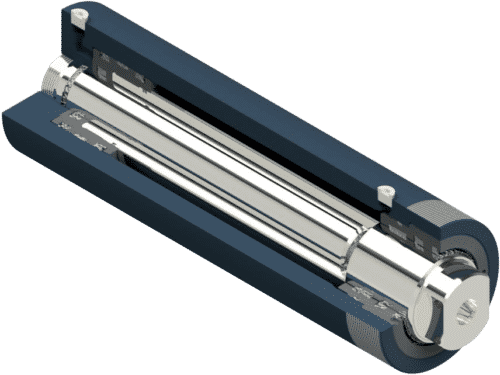

Mill-duty cylinders are made with heavy-duty or high heat applications in mind. These hydraulic cylinders have a duty cycle that significantly exceeds that of NFPA cylinders. And while mill-duty cylinders are not made to a specific standard, their base features are generally inherent across different manufacturers. These features include bore sizes, stroke length, and mounting style.

Steel mills, paper mills, offshore drilling operations, and other heavy industrial users typically prefer mill-duty cylinders because of the rugged design and heat resistance.

Choosing Between NFPA and Mill Duty Cylinders

The type of cylinder you need comes down to the design, sizing requirements, and application. NFPA pneumatic cylinders will work fine in most standard applications. If you don’t need a high pressure rating and are only using the cylinder in low to medium-duty applications, this option could work for you.

Mill-duty cylinders come in handy when you need a more rugged, specialized design. These situations might include heavy-duty applications, or cylinder designs requiring non-standard sizing and specific materials or technology. The ability to design these cylinders for your application without restrictions means better performance and reliability in harsh operational and environmental conditions.

If you are ever on the fence about which cylinder you should choose, consult with an expert. Making the right choice from the beginning will save you the cost and headache of down equipment on your job site.

Application-Specific Mill Duty Cylinders

Mill-duty cylinders from Aggressive Hydraulics adhere to many of the regulations set by NFPA. Each hydraulic cylinder has a heavy-duty design with a bolted head and end cap. Our Purpose-Built™ cylinders are designed and manufactured in an ISO 9001:2015 certified facility to ensure quality.

Improve performance in even the most demanding work environments with our American-made custom mill spec cylinders. Send us a message to discuss your application with our engineers.